Last August, I decided to build a maize mill for my parents to run as a business. I negotiated with the chief of Chamama to buy a small parcel of land at the Chamama Trading Center, 15 kilometers from my home. After the deal was concluded, I hired workers to construct a small building out of bricks, cement, timbers, and iron sheets. When the construction was complete, I bought an electric maize milling machine and assembled it inside. Unfortunately, this machine required more power than a windmill could generate. Therefore, I needed to wire the building for electricity from ESCOM, the local power company. It took almost 10 month for ESCOM to hook up the power, but finally, I was able to get the mill running when I was home in June 2011. Now my parents have a business to run; I hope they will be successful!

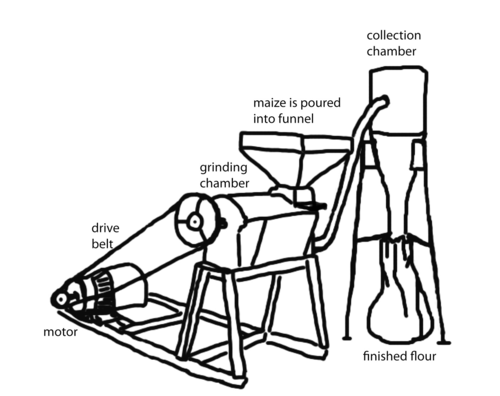

Maize mills these days are different from old ones. Modern mills use 30-horsepower electric motors that plug into the wall. A five-inch diameter pulley connects to the motor and turns a belt to drive a horizontal shaft that goes inside the grinding chamber. Above the chamber, there is funnel to pour in the maize, or what you might call corn. At the bottom of the funnel, there is a slide stopper to control the flow of the corn into the grinding chamber. Inside the chamber, the shaft goes from one end to the other. Large washers that are attached to the central shaft divide the chamber into several narrow compartments. In each compartment, a metal blade rotates on a swivel. When the motor turns the shaft, centripetal force spins these blades to grind the maize. The fine particles of flour fall through a screen, and a fan blows them up through a tube and into a collection chamber. This chamber is a large cylinder that stands on a tripod. Air escapes out an exhaust hole. The flour drops to the bottom of this chamber, where another funnel directs the flour into a sack. Typically, the same sacks that were used to bring in the maize are used to collect and transport the finished flour. The mill can grind a large sack of corn in less than five minutes.

With this new mill, my parents will grind corn flour for all the villagers in the area surrounding Chamama. Some people might travel up to ten kilometers or more carrying the sacks of corn on their heads. One person can carry up to 40 kilos of corn in one sack, or some people bring in several sacks on an ox cart. After just one month of operation, the mill receives as many as twenty customers per day, who all pay cash at the time of service. The only expenses for the business are the quarterly merchant tax, electricity, and wages for two employees. If my parents and their employees provide good customer service, treat people with respect and courtesy, and charge a fair price, the mill should make enough money to support my family.